AlfaVap semi-welded heat exchangers are rising film plate evaporators and are suitable when concentration and viscosity of media are high.

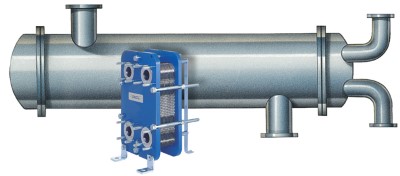

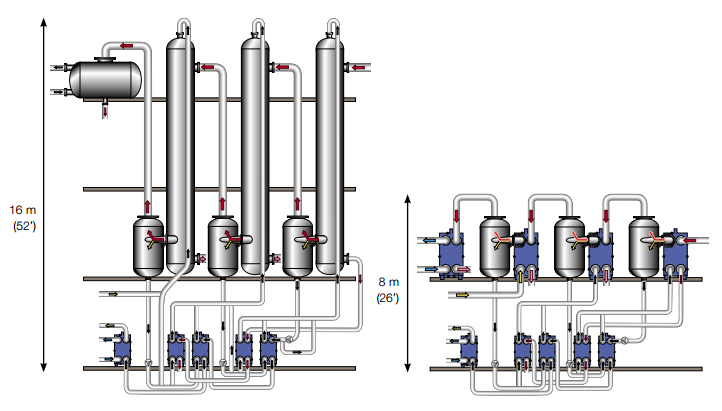

AlfaVap’s advantage is that they work also when the temperature differential between the hot and cold fluids approaches as low as 2.5°C (4.5°F) meaning that lower grade steam and more effects in series can be used in an evaporation system compared to the shell-and-tube systems. This saves steam costs.

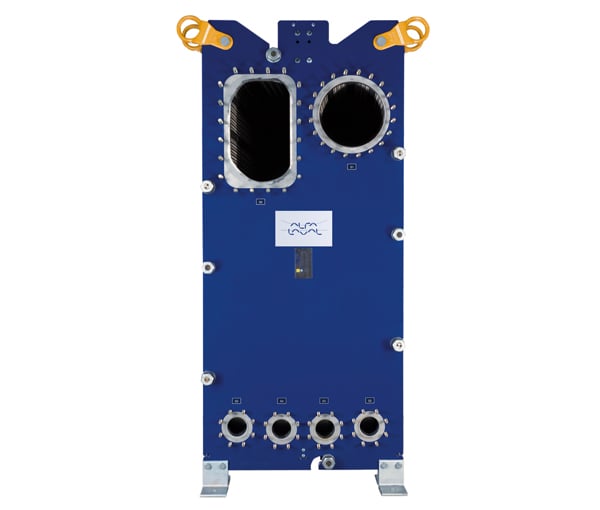

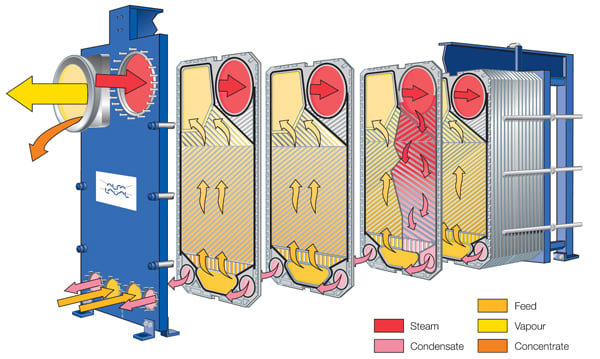

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. The sealing between the plates on the AlfaVap alternates between laser welds and gaskets. AlfaVap is tailor-made for evaporation. It has two inlet feed connections located centrally at the bottom of the frame plate and a large outlet for the vapour and concentrate at the top. The heating steam condenses in the welded channels and the evaporating product passes through the gasketed channels.

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. The sealing between the plates on the AlfaVap alternates between laser welds and gaskets. AlfaVap is tailor-made for evaporation. It has two inlet feed connections located centrally at the bottom of the frame plate and a large outlet for the vapour and concentrate at the top. The heating steam condenses in the welded channels and the evaporating product passes through the gasketed channels.

Plate heat exchangers have an essential role in most applications. If they function poorly, they may lead to lower product quality, reduced safety and higher energy costs. And if they fail, they can lead to costly downtime and major losses in production. This makes it important to perform maintenance – and important to do it correctly.