CR series

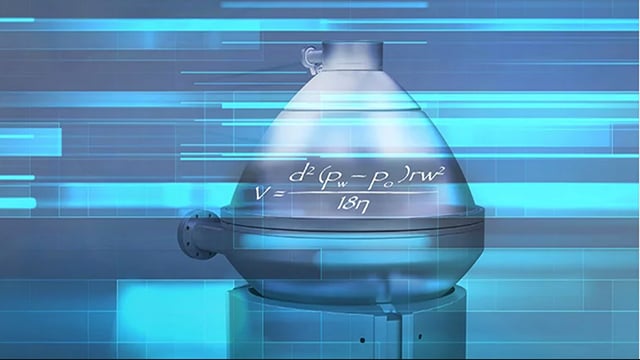

Alfa Laval CR centrifuges excel in delicate beverage and citrus processing tasks, including de-oiling and peel oil recovery. Their unique design, specially tailored to provide high separation performance in three-phase polishing and concentration, is ideal for the extraction of citrus oils and essential oil extract. With Alfa Laval’s unique bottom-fed Hermetic Design™, the concentrator centrifuge ensures maximum product recovery combined with the market’s best preservation of volatile aromas.

Experience the benefits of CR series, concentrator centrifuges for citrus oil extract

- High separation efficiency enables maximum oil purity up to 99.5% in the second stage, low losses below 0.5%

- Optimal preservation of essential volatile oils thanks to the airtight Hermetic Design™

- Hygienic, easy-to-maintain equipment with improved design for cleaning-in-place (CIP)

- Energy savings of up to 60% thanks to the Hermetic Design™, reaching up to 75% when combined with eMotion™

Alfa Laval CR separators are engineered to boost profitability in peel oil recovery and de-oiling applications by delivering high separation efficiency and gentle handling of volatile compounds. Typical uses include cold-pressed peel oil concentration, and the extraction of essential oils for perfume and cosmetic production, citrus juice de-oiling, specialty orange juice processing, —making the CR series a reliable solution for maximizing product value in flavor, fragrance, and beverage industries.

Innovative highlights of the CR series concentrator centrifuges

Hermetic Design™

Alfa Laval’s CR series centrifuges, built on patented Hermetic Design™, gently handle volatile compounds by eliminating the air-liquid interface—delivering superior oil quality and higher yields. Ideal for citrus juice deoiling, specialty juice clarification, and essential oil extraction for cosmetics and perfumes. With energy-efficient operation, durable components, and easy maintenance, CR centrifuges offer low OPEX and reliable, long-term performance. Key benefits include high yield and efficiency with minimal product loss, airtight design preserves essential volatile compounds, fast, effective CIP with 100% wetted surfaces, and up to 60% lower energy use with center-to-center design.

eMotion™

Alfa Laval eMotion™ is a unique energy-saving module, available as an add-on for many of Alfa Laval’s separators. By creating a near-vacuum around the separator bowl, eMotion™ reduces air friction enough to improve energy efficiency with up to 75% when combined with Hermetic Design™. There are additional benefits of eMotion™, such as reduced noise levels, lower cooling requirements, and improved cleanability.

Complete plug-and-play system scope

The advanced technology of the CR series goes far beyond the centrifuge itself. To make sure you get the best polishing or concentration performance, Alfa Laval can deliver the entire system scope, complete with everything you need to ensure reliable and efficient separation. This includes automation solutions as well as all piping, valves and other relevant process components. For CR 250 models, the complete system is installed on a portable skid with wheels. CR 450 and 750 models feature components mounted on a self-supporting stainless-steel frame.

Optiwia™: upgrade for water efficiency

Alfa Laval Optiwia™ is a standalone, plug-and-play water-saving upgrade for beverage production separators, designed to reduce water consumption by up to 70%. By reusing water for cooling, Optiwia minimizes costs, improves efficiency, and supports sustainable beverage production. Easy to install without needing connection to the control system, it ensures constant water pressure and solves yeast discharge issues. Upgrade to Optiwia for a smarter, greener, and more cost-effective beverage process.

Ask our separation experts

Curious about the difference an Alfa Laval CR series concentrator centrifuge can make in your production? It comes down to leading technologies that Alfa Laval has developed over decades of separation innovation. Hear from our application experts to learn more.

How can the CR series help me recovery even more peel oil?

The CR series is designed for precision oil recovery from citrus peel—a highly valuable by-product. Operating at high pressure, it ensures minimal loss by clearly separating light and heavy phases. In a real-world case from Sicily, 98% oil recovery was achieved, delivering exceptional return on investment.

For example, with a 20,000 L/h capacity, you can recover up to 100 liters of oil per hour. This means the machine can pay for itself within just a few months. Watch the video.

Why Hermetic Design™ so important for de-oiling and peel oil recovery?

In citrus juice de-oiling, preserving aroma is everything. The CR series uses fully hermetic technology to prevent oxygen from entering the process—protecting the highly volatile essential oils.

By keeping the oil stream sealed off from air, the machine ensures the aroma stays intact. In Italy, this has enabled producers to extract premium-grade bergamot oil, sold directly to the perfume industry at high value. Thanks to the Hermetic Design, nothing is lost—only preserved. Discover how CR delivers quality and profit.

The right CR to match your capacity demands

If you are looking for a reliable and cost-efficient concentrator or polisher, our separation experts can work with you to find the right CR centrifuge for your needs.

CR 250

- Capacities up to 10 000 l/h for small-to-medium-sized producers

- Skid-mounted separator and system

CR 450

- Capacities up to 16 000 l/h, suitable for mid-sized production

- Separator with complete associated system

CR 750

- Capacities up to 30 000 l/h for large-volume production

- Separator with complete associated system

Service

Extending the performance of your equipment

Our dedicated global service network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind and maximize your return on investment. We can work with you to integrate our services into a Performance Agreement for predictable and worry-free operations.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.

Test, validate, and scale up your next separation solution

Whether upgrading your production line or running a proof of concept, Alfa Laval helps you choose the right separator solution with confidence. Simply get in touch to arrange a consultation and trial at one of our test centres, or to rent a unit for onsite testing.