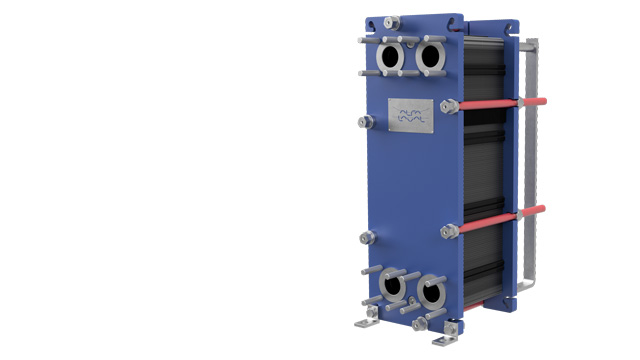

Like its predecessor the Alfa Laval M15, the T15 is a dependable workhorse that is suitable for a wide range of positions. That includes heat recovery (interchangers), product cooling and much more!

The T15 includes many of our latest pioneering innovations for increased efficiency, improved reliability and greater serviceability. Regardless of whether your heat exchanger has asymmetric flows or not, the inclusion of FlexFlow™ asymmetric plates, will offer new possibilities in how to optimize your heat exchanger according to its specific duty. T15 models also feature our OmegaPort™ non-circular ports and the CurveFlow™ distribution pattern that ensure both superior thermal transfer as well as higher uptime with reduced maintenance expenses.

All of this means that T15 will open new doors for an even wider range of positions and duties than its predecessor. From energy and power to ethanol production, applications in food and beverage, and a whole host of other industries, the Alfa Laval T15 promises to set a new standard for your profitability!

In general, the T6 range is more efficient than the predecessor M6 and the compact footprint makes it an attractive alternative in many applications and industries such as industrial utility applications, heating/cooling in food and water, HVAC duties or in general utility process applications.

For example, the T6-B allows for higher thermal duties compared to its predecessor M6 which makes it specifically interesting for heat recovery applications. The T6-P incorporates FlexFlow TM plate design that utilizes asymmetry to enable a more precise thermal fit. The many configurable variations will ensure highest possible efficiency for any duty.

Thanks to other next-generation features such as the OmegaPortTM non-circular ports and the CurveFlowTM distribution pattern, the T6 range provides great anti-fouling capabilities enabling prolonged service intervals, higher operational efficiency and lower service costs.

Alfa Laval’s M10 has long been the market’s most versatile gasketed plate heat exchanger. Able to provide high thermal performance in a wide range of applications, it has set a global standard for energy efficiency and sustainability. But for us, just setting the standard is never good enough. That’s why we’ve created T10 – M10’s successor that’s breaking new barriers.

Built with a revolutionary new plate concept, T10 eliminates the compromise between efficiency and pressure drop. With the improved design, we can better accommodate uneven flows, making it possible to optimize the performance of the heat exchanger according to its specific position in your processes.

The result is up to 30% higher efficiency and reduced fouling for reliable, cost-effective performance. And that’s just the start.

Whatever the application, T10’s truly sustainable, energy-saving design creates additional possibilities to meet environmental targets. And the new plate concept ensures lower total cost of ownership thanks to a smaller footprint and reduced maintenance needs.

The next-generation T25 is available with two plate configurations that helps you to boost energy efficiency and minimizing environmental impact. The T25-B is specially engineered for high-pressure applications that require the closest temperature approach such as:

Alfa Laval T25-P offers a durable and flexible heat transfer solution for industrial processes requiring the unit to perform reliably under tough conditions. Some examples are:

Learn more about the next-generation features that help T6, T10 and T25 break new barriers when it comes to thermal performance and sustainability in a wide variety of applications and positions.

This technical paper provides an overview of the different ways that newer heat exchangers can contribute to overall energy savings in industrial heating and cooling applications. Whether you are considering equipment for a new installation, looking to upgrade your existing heat exchangers or exploring the possibilities of expanding your capacity, this information is useful.

Do you want to learn more about your options or get advice from our experts about which gasketed plate heat exchanger is the best fit for your business contact us!

The Alfa Laval AlfaQ range is certified according to the AHRI Liquid-to-Liquid Heat Exchangers (LLHE) Certification program, which ensures thermal performance according to manufacturers’ published specifications. Alfa Laval’s next-generation features are also available for relevant sizes and configurations of models in the AlfaQ range.