Data center cooling

Energy efficient cooling is critical to building more sustainable data center operations. Alfa Laval has been a trusted partner to the IT industry for decades, working with customers to design reliable, environmentally friendly data center cooling systems. With 80+ years’ experience in thermal technology, we offer expertise to enable new opportunities for free cooling and energy savings in server rooms of all sizes, all around the globe.

The key to sustainable data centers

- Advanced plate heat exchanger technology that minimizes the need for traditional mechanical cooling

- Shrink your power bill and environmental impact with unique solutions that maximize efficiency for minimized energy consumption

- A wide range of solutions to boost sustainability by taking advantage of free cooling as well as heat recovery opportunities

- Innovations for improving reliability and serviceability help you maximize uptime and simplify maintenance

- Third-party AHRI certification offers confident assurance of heat exchanger’s thermal performance

Ready to see the future of green IT in your data center? Contact us today.

1. Cooling tower interchanger

2. Free cooling with water

3. Free cooling with air

4. Heat recovery

5. Liquid cooling

In the spotlight

Join us for a webinar series on cooling systems

Cooling applications are experiencing a rapid transformation, with sustainability drivers creating all new challenges. But Alfa Laval can help. Join our subject experts for the first ever webinar series devoted to the latest trends – and solutions – shaping our industry. Take part live – or watch on-demand according to your schedule!

Committed to industry collaboration

Alfa Laval works closely with data center partners to advance the future possibilities of greener IT. That is why we are excited to play a collaborative role as members of two industry organizations: the Swedish Data Center Industry Association and the Open Compute Project.

Listen to the experts

Dive into the world of data centers and heat transfer and learn more about the next steps toward net-zero energy. Take part in our podcast Exchanges on Exchangers and find out more about efficient data centers.

Do you need BIM files?

Heat exchangers from Alfa Laval are now available in the digital infrastructure for BIM objects. Preview and download building information modelling (BIM) files for your heat transfer solutions.

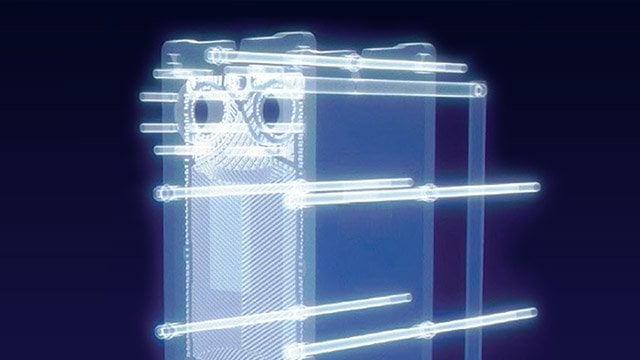

Demand new standards for your cooling system

With decades of experience at our side, Alfa Laval has pioneered the world’s most modern gasketed plate heat exchanger designs. Discover how our next-generation line of technologies can bring higher efficiency, better reliability and greater serviceability to your data center.

Protecting and enabling greener solutions

On average, as much as 40% of a data center’s power consumption goes toward cooling the servers. Fortunately, the technology to make these cooling systems more energy efficient and reliable already exists. Watch this video to learn about the potential for increased sustainability with Alfa Laval’s next-generation plate heat exchangers.

Efficient and reliable technology: that is what we do

Only Alfa Laval offers a full range of heat exchange technology for data centers with performance certification from the independent Air-Conditioning, Heating, and Refrigeration Institute (AHRI). This gives you confident assurance of efficient performance, but ultimately, the equipment is just the beginning. Find out how we can work with you from day one to make sure your cooling system will deliver reliable, long-term sustainability.

Unique expertise to ensure dependable sustainability over time

Fouling can greatly reduce both the expected lifetime of your heat exchanger as well as its thermal performance. With Alfa Laval as your partner, you have access to the world-leading experts on chemistry and materials technology. They can work with you to identify the potential causes of fouling risks and develop custom strategies to help you prevent it.

Learn more about our Materials Technology & Chemistry Center

Advanced solutions for data centers

Gasketed plate-and-frame heat exchangers

Alfa Laval’s next generation of industrial gasketed plate heat exchangers set new standards of thermal efficiency, mechanical reliability and ease of serviceability. They are the key to more sustainable data center cooling operations.

Brazed and fusion bonded plate heat exchangers

Alfa Laval has the market’s most comprehensive line of brazed plate heat exchangers, with a range of solutions optimized for today’s more sustainable, natural refrigerants. Discover how you can benefit from ‘more with brazed’.

Cylindrical filter baskets

Alfa Laval offers a range of automatically self-cleaning filters and strainers, used to protect heat exchangers in cooling systems from clogging, fouling and corrosion. Reduce the risk of unplanned downtime and prolong service intervals.

Want to find out more about our comprehensive service offering? Click here.

Support to maximize your uptime

Alfa Laval has a truly global service network, with experienced technicians in your area who can be there with the support you need – right when you need it. From guidance on system design and installation, to training for your operators, troubleshooting, routine maintenance and even customized cleaning protocols, we are at your side throughout the long life of your equipment. Here are just some of the ways we can support you to maximize your uptime:

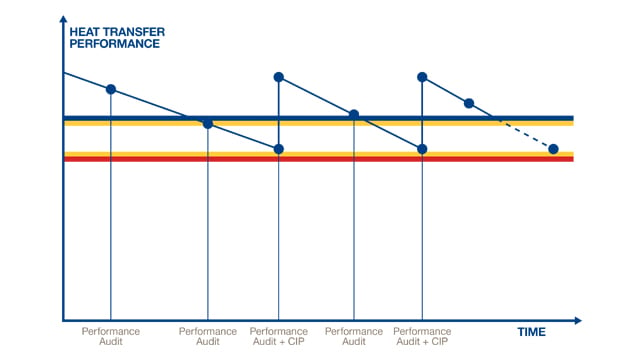

Performance audits

Our trained experts review and analyse the actual thermal performance of your equipment. Using modern tools, they can detect for fouling or similar risks, enabling you to better plan your maintenance needs in order to optimize system uptime.

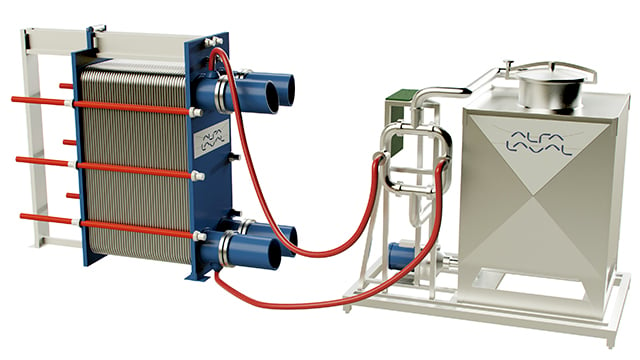

Cleaning-in-place

Alfa Laval cleaning-in-place (CIP) systems enable quick and easy in-line cleaning of heat exchangers for managing fouling. With environmentally friendly, biodegradable cleaning agents, our CIP eliminates unnecessary repeated opening of your equipment. As a result, you drastically reduce spare parts consumption and the man-hours needed for maintenance.

Backflushing

Alfa Laval recommends frequent backflushing on the incoming flow of cooling water for short periods of time. In this sequence, the reversed water scrapes off and flushes out accumulated debris from the heat exchanger plate surface. Using backflush equipment saves time and money while minimizing downtime.

Questions? Challenges? Support? Don’t worry – that’s what we’re here for.

Want to find out how the right technology can help your data center project achieve greener goals? Fill out the form, and one of our experts will get in touch with more information.