Effective and efficient process industry wastewater treatment

Wastewater is a challenge in many process industries like chemical and petrochemical, refineries, steel, and mining & mineral. Ever increasing regulations to meet environmental goals is a further challenge. Alfa Laval’s deep and long experience with evaporation and centrifugal separation help companies in these industries operate more sustainably, recover water and valuable materials from wastewater to increase circularity and do so with an eye on cost reduction as well.

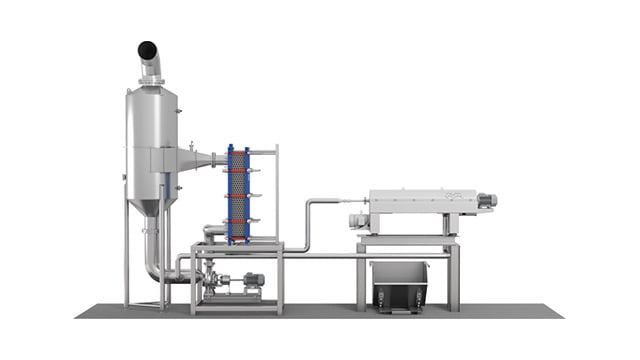

AlfaFlash ZLD systems offer many benefits:

- Heavy duty separation for challenging applications

- Adaptable heat transfer area to meet future or changing needs

- Often smaller footprint than competitive technologies

- Global presence and service offering

Wide range of solutions for a broad range of applications

Alfa Laval’s wide range of solutions have helped industries across a broad sector of process manufacturing operate more efficiently and sustainably. Here are just a few of the applications where Alfa Laval technologies have helped our customers:

- RO reject

- Produced water from oil & gas

- Waste/spent caustic in leaching processes

- Lithium chloride processing in mining

- Cooling tower blow down

- Mining tailing ponds

- NaCl wastewater

- NaSO4 wastewater

Evaporation and ZLD are typically the technology of choice for heavy duty concentration of wastewater towards saturation or to even crystallization. This process of treating wastewater can be done so that the water can be returned to a state clean enough to be used again in the process. Alfa Laval can customize and meet set standards through our flexible yet robust systems.

AlfaFlash ZLD systems in these critical functions are now being simplified to make ordering, delivery, installation and commissioning easier. With a modular offering, the path to a more efficient, more sustainable process has never been simpler. To read more about the AlfaFlash ZLD system, click here.