Neutralization systems

Enhance the taste, stability and shelf life of your edible oils through the effective removal of free fatty acids in your crude oil. Alfa Laval neutralization systems remove free fatty acids and other impurities that impact edible oil quality, consistency, appearance, taste and shelf life. Tailor these systems to your needs—whether cold, alkali or miscella refining. What you get is crude oil free of impurities and sodium soap for onward processing into quality edible oils and soapstock.

Reliable, effective neutralization of free fatty acids enhances your edible oil refining processes

- Ensure more uptime and longer service life due to robust system design

- Maximize edible oil quality, taste, shelf life and yield

- Boost operational reliability and efficiency

- Minimize oil loss and operating costs

- Easy to install, operate and maintain

Webinars for the Edible Oil industry

Our experts share know-how to optimize edible oil refining processes, remove impurities and volatile components for better product quality, safety and yield.

Neutralization System Process

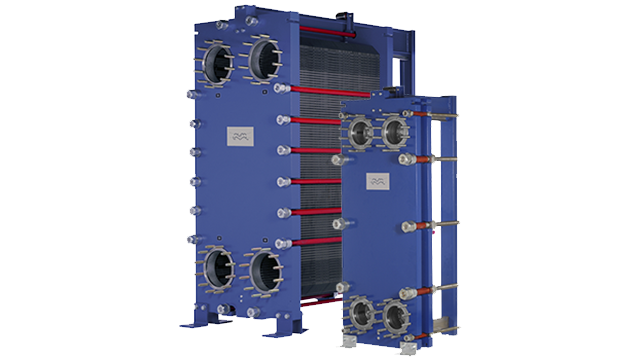

The Alfa Laval Neutralization System consists of heat exchanges, dosing pumps, mixers, agitators and disc stack centrifuges.

How it works

How the process of neutralization works

The process of neutralization is a critical step in edible oil refining. As free fatty acid levels increase, more intensive processing and higher caustic soda dosing are required to ensure effective removal of free fatty acids and other impurities. The crude oil is heated, mixed with acid, then dosed with caustic soda (lye), mixed again, then held in retention tanks, where the bonds between the oil and residual impurities are broken. Disc stack centrifuges then continuously neutralize the oils and fats.

Generally speaking, there are two methods to neutralize fats and oils:

Long-mix refining process for crude soybean or rapeseed oil

Used for crude soybean or rapeseed oil, this method neutralizes the free fatty acids by heating and dosing crude oil with acid and lye. The oil remains in contact with caustic soda for an extended period in special retention mixers. It is then heated and transferred to disc stack centrifuges, where soapstock and wash water are separated from the refined oil in a single stage.

Multi-mix refining process for virtually any oil

Suitable for refining virtually any oil, this method exposes the crude to the caustic soda for a short period. It then goes through one to two stages of washing. When processing cottonseed oil or low-quality crude fats and oils, a second lye treatment, known as re-refining, is required.

After neutralization, the oil is washed. Disc stack centrifuges then separate the wash water from the oil, which is transferred to a vacuum dryer for drying. The free fatty acids and other impurities (sugars, pigments, and trace metals) separated from the oil are sent downstream as soapstock, which can be processed in a soapstock splitting process to produce fatty acids.

Alfa Laval neutralization systems also support the refining of cottonseed oil and cold refining of sunflower or maize/corn oil.

Contact us

Find out more about Alfa Laval neutralization systems.