Micro

The Alfa Laval Micro is a compact exhaust gas heat exchanger especially designed for waste heat recovery from small gas turbines as well as from small engines and clean process flue gas. In any operation, there is almost always room to continue reducing power consumption and related costs. The secret is in reclaiming the energy lost as exhaust gas heat. As the pioneer in waste heat recovery, Alfa Laval has the technology and expertise to help you further increase your energy efficiency.

Economical use of waste heat

- Lower footprint and weight

- Cleaning possible during operation of engine, turbine or process

- Output can be adjusted according to the need

- Extend the time in between major cleaning e.g. via dry-run mode

- Low inertia

Applications

The Aalborg Micro can operate with a diversity of media, including water, steam, triethylene glycol (TEG) and thermal fluid oil (TFO). To date, Alfa Laval Micro heat exchangers have been used in different applications across a wide range of industries.

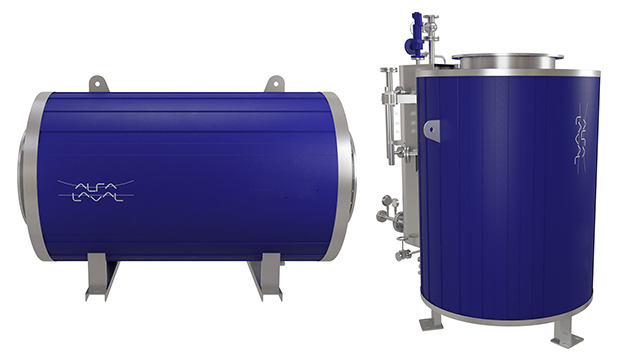

Design

The Aalborg Micro is build in a durable design featuring a heating surface consisting of a number of coaxial tubes arranged in a vertical or horizontal cylindrical shell plate. This, ensures a long-term, trouble-free performance and offers capacities ranging from approximately 250-5000 kW.

The heating surface of the Aalborg Micro has been developed for easy maintenance. Cleaning can be performed either with a pyrolysis process when operating in dry-run mode or using optional soot blower rings with compressed air, steam or water.

Technical data of GHR

- Capacity: 250 kWe – 10 MWe

Exhaust flue gas side:

- Maximum inlet temperature: 600 Deg C

- Minimum outlet temperature: dependent on engine fuel and exhaust gas composition

- Pressure loss: according to customer requirements

Geometry

- Weight: (incl. insulation) 400 kg to 3900 kg

- Diameter (incl. insulation): 950 to 1870 mm

- Height (incl. insulation): 1700 to 2800 mm

- Media inlet/outlet header: DN100

- Exhaust inlet/outlet header: DN450 to DN1000

- Insulation: 150 mm

How it works

Selected recovery references

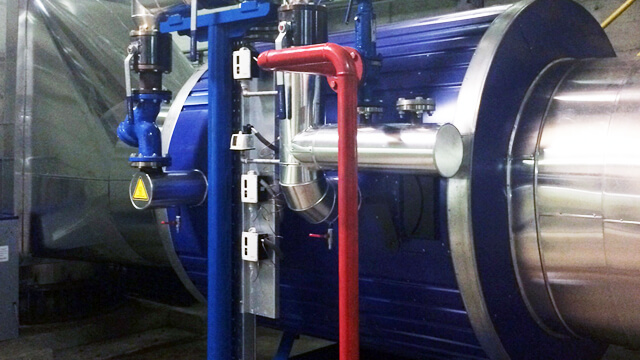

Power generation in China

70 x Alfa Laval GHR after gas engines to produce hot water.

Process flue gas in China

3 x Alfa Laval GHR 406 and 2 x Alfa Laval GHR 410 used to recover exhause flue gas heat from aluminium melting furnace to generate hot water.

Industrial process in Italy

Alfa Laval GHR 814 for hot water application after gas engine.

Hotel industry in Mexico

Alfa Laval GHR 210 for hot water application after gas engine.

District heating in Denmark

Alfa Laval GHR 714 for hot water application after multi fuel engines.

Power generation in China

11 x Alfa Laval GHR 422 with cyclone for steam production.